|

Products

|

Products  Fiber Laser Machine

Fiber Laser Machine

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

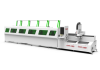

Open Type Tube Fiber Laser Cutting Machine

Open Type Tube Fiber Laser Cutting Machine

Available

Available

Open Type Tube Fiber Laser Cutting Machine

Open Type Tube Fiber Laser Cutting Machine Product Introduction (1) Machine Overview The Unico laser pipe cutting machine is a versatile solution designed to meet the demands of batch pipe processing for end users. With exceptional cost-effectiveness, this machine can efficiently cut various types of tubes, including round tubes, square tubes, rectangular tubes, oval tubes, I-beams, and channel steels, up to 9.5 meters in length. The Unico laser pipe cutting machine

- Color: Default Color

- Size: Default Size

- Origin: China

- Usage: Default Usage

- Type: Default Type

- Efficiency: 99.9% Type

Description:

Open Type Tube Fiber Laser Cutting Machine

Product Introduction

(1) Machine Overview

The Unico laser pipe cutting machine is a versatile solution designed to meet the demands of batch pipe processing for end users. With exceptional cost-effectiveness, this machine can efficiently cut various types of tubes, including round tubes, square tubes, rectangular tubes, oval tubes, I-beams, and channel steels, up to 9.5 meters in length. The Unico laser pipe cutting machine stands out for its broad applicability, making it an ideal choice for numerous pipe processing companies. From configuration selection to assembly, training, and after-sales service, this machine is crafted to be affordable and user-friendly. The transmission system, featuring imported gear racks, servo motors, reducers, and linear guides, ensures stability, high precision, and quality cutting capabilities.

(2) Machine Performance

- Independent development and manufacturing of machine tool beds, utilizing special processing technology for high precision, stability, reliability, and extended lifespan.

- Precision rack and pinion drive, equipped with a high-precision reducer and responsive servo motor for precise and efficient performance.

- Incorporates an international first-class quality fiber laser with a proven track record in industrial applications, offering long life, maintenance-free operation, stability, and reliability.

- High-precision laser cutting head with imported optical lenses, allowing for fine focusing, easy adjustment, and impeccable cutting.

- Simple and easy-to-learn CNC system operation with low operator requirements.

- Supports multiple cutting graphics formats, providing powerful graphics drawing and editing functions.

- Features an automatic refueling system for enhanced operational efficiency.

(3) Cutting Materials

Suited for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanized sheet, pickled sheet, and other metal sheets. Widely adopted in various manufacturing industries, including engineering machinery, aerospace, automotive, shipbuilding, steel structures, machinery manufacturing, elevator manufacturing, advertising, household appliances, medical equipment, stair handrails, steel and wood furniture, and metal external processing services.

2. Functional Characteristics of Each Part

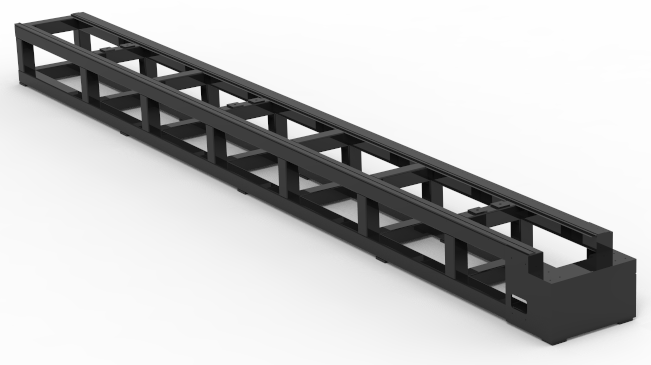

(1) Lathe Bed

The lathe bed is designed using structural dynamic design principles and finite element method variable analysis technology. Welded with high-quality raw materials, it undergoes stress relief annealing, secondary vibration aging treatment, and precision machining. This ensures excellent shock resistance, high rigidity, stability, good toughness, light weight, corrosion resistance, oxidation resistance, and high processing speed.

(2) Front and Rear Chucks

The Unico laser chuck features independent innovation, strong R&D capabilities, multiple patents, and complete intellectual property rights. Noteworthy performance advantages include a square hole design for enhanced passing capacity, intelligent adjustment of clamping force, and a full-stroke clamping range without manual adjustment. The chuck offers twice the clamping force of ordinary chucks, precision grinding gear transmission, high dust-proof level, and increased stability.

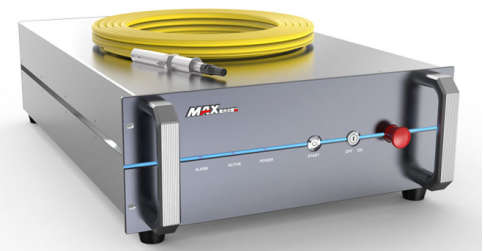

(3) Fiber Laser Generator

- Modular and redundant design for a compact, lightweight, and easily movable solution.

- Belongs to the MFSC series, serving industrial applications with high-efficiency, high-beam-quality single-module fiber laser.

- Main features include high beam quality, power efficiency, reliability, long life, and a compact, sturdy package.

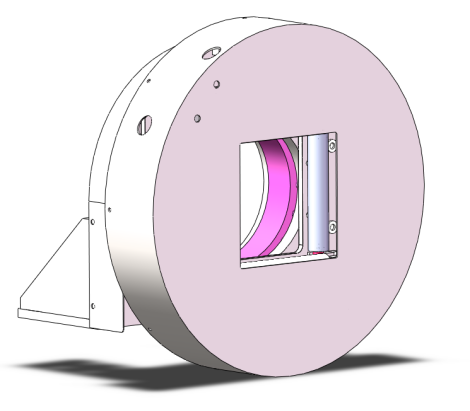

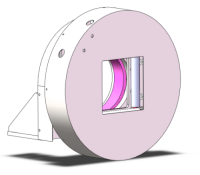

(4) Fiber Laser Cutting Head

- Internally sealed structure prevents contamination of optical parts.

- Driven by an imported motor for high perforation efficiency.

- Adaptive optical system for automatic focus or spot size adjustment, ensuring consistent cutting quality.

- Sealed and dust-proof three-piece protective mirror.

- Automatic machine tool stop in case of cutting head collision.

(5) Operating System

- Cyptube is professional three-dimensional pipe cutting software compatible with IGS format files.

- Supports automatic extraction of the pipe section to be cut and trajectory without manual editing.

- Features automatic leveling and center correction functions for improved cutting accuracy.

- Automatically calculates lifting height during pipe rotation and single-sided cutting, avoiding head collision and reducing unnecessary lifting.

- Enhances cutting accuracy for L steel, channel steel, I-beam, and other special steel.

- Effectively compensates for regular cutting deviations, reducing material accuracy requirements and minimizing waste.

- Solves pipe hole position accuracy problems and improves accuracy of hole position edge distance.

- Reduces manual alignment time and front-end waste through cutting head alignment.

- Solves issues like high power burning, thin tubes falling before cutting, and small tails at cutting position.

- Controls the release of the middle chuck during end-of-pipe processing, improving Y-axis movement stroke and cutting capacity.

(6) Operating Software (Optional)

- TubesT supports nesting of single or multiple parts, optimizing material usage.

- Performs co-edge processing on welded parts, island co-edge processing, and automatic sorting of idling paths.

- Comes with a 3D drawing function for easy operation, allowing users to perform stretching, drilling, cutting, and V-grooving operations.

(7) Cooling Method

Professional-grade water cooling system with dual temperature and dual control, ensuring efficient cooling with automatic temperature regulation.

663

663