Available

Available

Single Round Tube Laser Cutting Machine

Single Round Tube Laser Cutting Machine 1. Product Introduction (1) Machine Overview The YONIK-6080C is a specialized round pipe cutting machine designed by YONIK to meet market demands, catering specifically to end-users involved in round pipe processing. This cost-effective model boasts the capability to cut pipes up to 6.5 meters in length, making it an ideal choice for a wide range of pipe processing applications. From configuration selection through assembly, tra

- Color: Default Color

- Size: Default Size

- Origin: China

- Usage: Default Usage

- Type: Default Type

- Efficiency: 99.9% Type

Description:

Single Round Tube Laser Cutting Machine

1. Product Introduction

(1) Machine Overview

The YONIK-6080C is a specialized round pipe cutting machine designed by YONIK to meet market demands, catering specifically to end-users involved in round pipe processing. This cost-effective model boasts the capability to cut pipes up to 6.5 meters in length, making it an ideal choice for a wide range of pipe processing applications. From configuration selection through assembly, training, and post-sales support, this machine is crafted to provide an affordable and user-friendly solution. The transmission system incorporates imported gear racks, servo motors, reducers, and linear guides, enhancing equipment stability and enabling high-precision, high-quality cutting.

(2) Machine Performance

- Independent research and development of machine tool beds with high precision, stability, reliability, and a long lifespan.

- Precision rack and pinion drive with a high-precision reducer and responsive servo motor.

- Utilizes an international first-class quality fiber laser known for its long life, maintenance-free operation, stability, and reliability.

- Features a high-precision laser cutting head with imported optical lenses, offering easy adjustment and perfect cutting results.

- The CNC system ensures simple and easy operation with low operator requirements.

- Supports multiple cutting graphics formats, providing powerful drawing and editing functions.

- Equipped with an automatic refueling system.

(3) Cutting Materials

Suitable for cutting various metal sheets, including stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanized sheet, and pickled sheet. Widely applied in industries such as engineering machinery, aerospace, automobiles, ships, steel structures, machinery manufacturing, elevators, advertising production, household appliances, medical equipment, and metal external processing services.

2. Functional Characteristics of Each Part

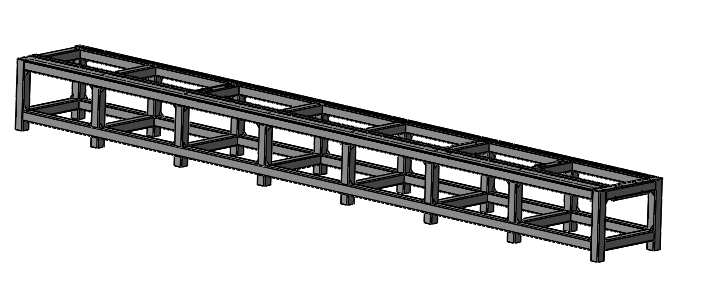

(1) Lathe Bed

The lathe bed, independently developed, undergoes stress relief annealing and precision machining to ensure excellent shock resistance, high rigidity, stability, and efficient processing speed.

(2) Equipment Structural Characteristics

- Gantry head structure made of Q235A carbon steel pipe, ensuring stable machine operation.

- Closed module design with TBI high-precision screw mold and high-precision servo motor.

(3) Self-Centering 3-Jaw Front Chuck (Pair-to-Pair Linkage)

- Tube Shape: Round

- Pipe Diameter: Circle diameter 80-800mm

- Self-centering mechanism, pneumatic clamping, and adjustable clamping force to adapt to varying wall thicknesses.

(4) Electric Rear Chuck

- Tube Shape: Round

- Pipe Diameter: Circle diameter 80-800mm

- Electric clamping method with large clamping force.

(5) Support

- Pneumatically adjustable height support.

- Automatically avoids the rear chuck for convenient loading and stable cutting.

(6) Fiber Laser Generator

- Modular and redundant design with a stable performance.

- High electro-optical conversion efficiency, minimizing power consumption and operating costs.

- Semiconductor modular and redundant design, maintenance-free, and high stability.

- Simple optical path with fiber transmission, enabling easy integration with robots or multi-dimensional workbenches.

(7) Fiber Laser Cutting Head

- Internally sealed structure to avoid optical part contamination.

- Driven by an imported motor for high punching efficiency.

- Adaptive optical system for automatic focus or spot size adjustment, ensuring consistent cutting quality.

(8) Operating System

- Utilizes a 32-bit high-performance CPU and FPGA for high stability.

- Plasma anti-interference ability with full optocoupler isolation control.

- Large storage space for processing files, supporting the running of complex programs.

- ARM7 processor technology for faster program running and interface refresh speed.

- Various functions including plasma arc detection, graphics library, cutting seam compensation, and breakpoint recovery.

(9) Cooling Method

Professional-grade water cooling system with dual temperature control ensures efficient cooling for stable operation. Automatic cooling based on digital meter readings.

711

711