|

Products

|

Products  Fiber Laser Machine

Fiber Laser Machine

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

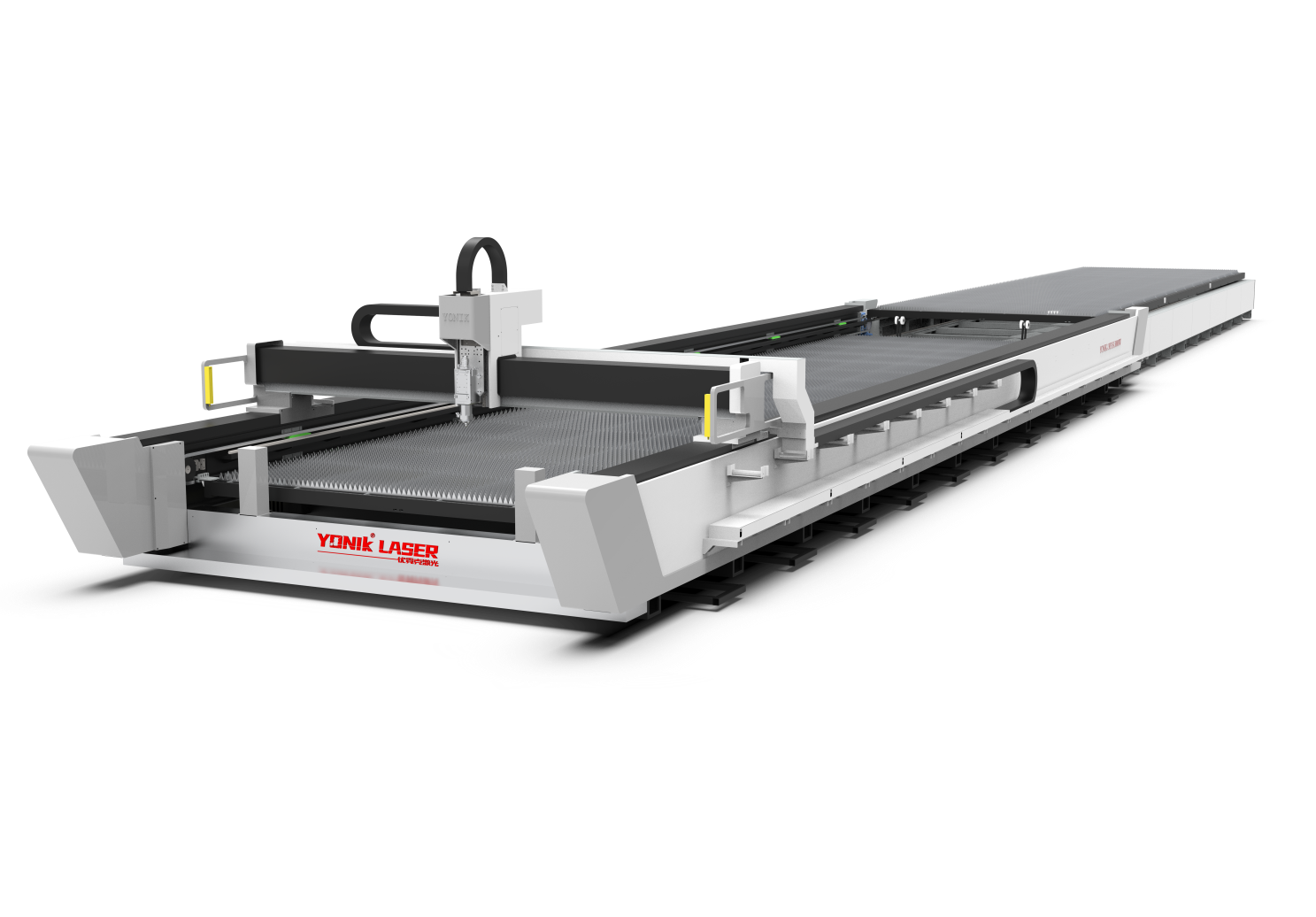

Changing platform Fiber Laser Cutting Machine (without large surrounding)

Changing platform Fiber Laser Cutting Machine (without large surrounding)

Available

Available

Changing Platform Fiber Laser Cutting Machine (without Large Surrounding)

Machine Overview: Our fiber laser cutting machine is a state-of-the-art equipment designed to efficiently cut materials into customized shapes, replacing traditional methods such as flame cutting, CNC punch, and plasma cutting. The machines bed is meticulously crafted from high-quality plates, featuring a robust frame structure created through professional welding, secondary aging t

- Color: Default Color

- Size: Default Size

- Origin: China

- Usage: Default Usage

- Type: Default Type

- Efficiency: 99.9% Type

Description:

The fixed support foot is intricately connected to the frame to provide support, allowing for precise adjustment of the frames straightness. The bed is secured by fixing the support foot and adjusting accuracy as needed. To protect the laser beam target area, a thick plate insulation covers it, preventing laser ablation and ensuring optimal processing accuracy for workpieces.

The dust removal system is designed based on aerodynamics principles, ensuring a smooth flue path and minimizing dust removal fan capacity loss. Additionally, the slag discharge system features a partition collection device to automatically gather waste materials during production.

The workbench, with its simple structure, utilizes a gantry-type Ding bed structure to significantly enhance the machine tools load-bearing capacity. The slag discharge systems lower bed includes a partition collection device for automatic waste material collection.

The transmission system boasts imported rack and pinion, servo motor, reducer, and linear guide, enhancing equipment stability and enabling high-precision and high-quality cutting. This setup underscores the machines professional design, mature functionality, and ensures high-precision, high-speed, and high-stability processing capabilities.

Machine Performance: Our fiber laser cutting machine stands out with its independently researched and developed machine tool bed, employing special processing technology for high precision, stability, and longevity. The precision rack and pinion drive, paired with a high-precision reducer and responsive servo motor, contribute to the machines high power, efficiency, and reliability.

Equipped with a world-class quality fiber laser, the machine ensures long life, maintenance-free operation, and stability. The laser cutting head, featuring imported optical lenses and an adaptive optics system, provides fine focus and automatic adjustments to guarantee consistent cutting quality throughout the processing range.

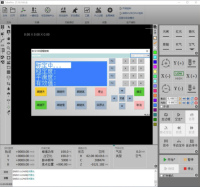

The machines user-friendly numerical control system simplifies operation, making it easy to learn with low operator requirements. Supporting various graphic formats, the system allows for powerful drawing and editing functions, enhancing flexibility in cutting different materials.

Functional Characteristics of Each Part:

-

Fiber Laser Generators: Our modular and redundant design fiber laser generator is compact, lightweight, and easy to integrate. It delivers stable performance, ensuring safe and efficient operation for industrial applications such as welding, cutting, and cladding.

-

Laser Cutting Head: The internal structure is sealed to prevent optical contamination, and it features an adaptive optics system for automatic focus adjustments. The laser cutting head guarantees minimal gas consumption and automatic machine stop in case of collisions during the cutting process.

-

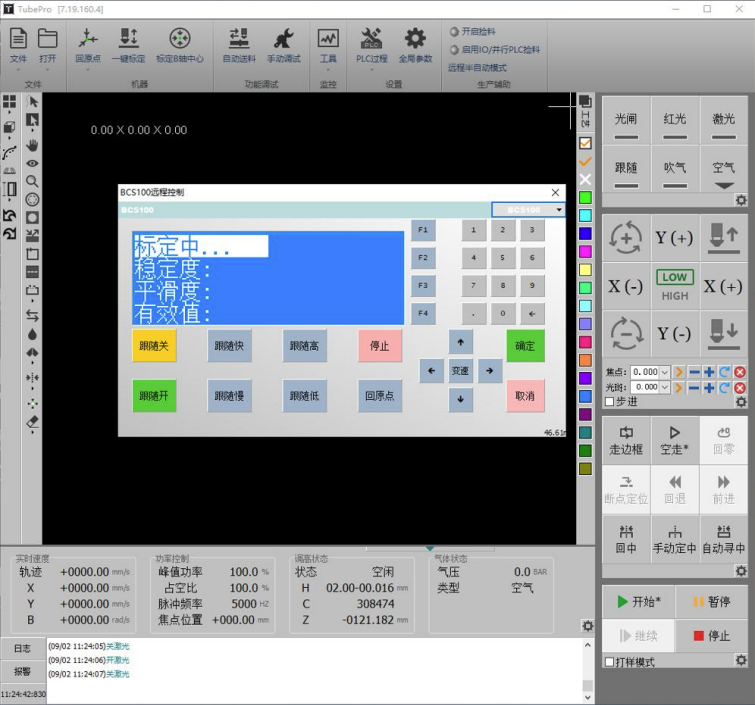

Operating System: The CNC cutting system supports graphic optimization functions, separates machining and nesting, and facilitates remote network push processing tasks. It features process-guided and multi-threaded production planning, simplifying operator requirements and improving equipment safety.

-

Operating Software (Optional): Specially developed for CNC cutting machines, the drawing programming nesting software includes CAD drawing, DXF/DWG optimization, interactive nesting, automatic programming, and cutting simulation verification, ensuring efficient cutting and high nesting rates.

Cooling Method: The refrigeration units temperature is digitally displayed, automatically initiating refrigeration when the water temperature exceeds the specified level and stopping refrigeration when the temperature drops below the specified threshold. This cooling method ensures optimal performance and longevity for the equipment.

655

655