Available

Available

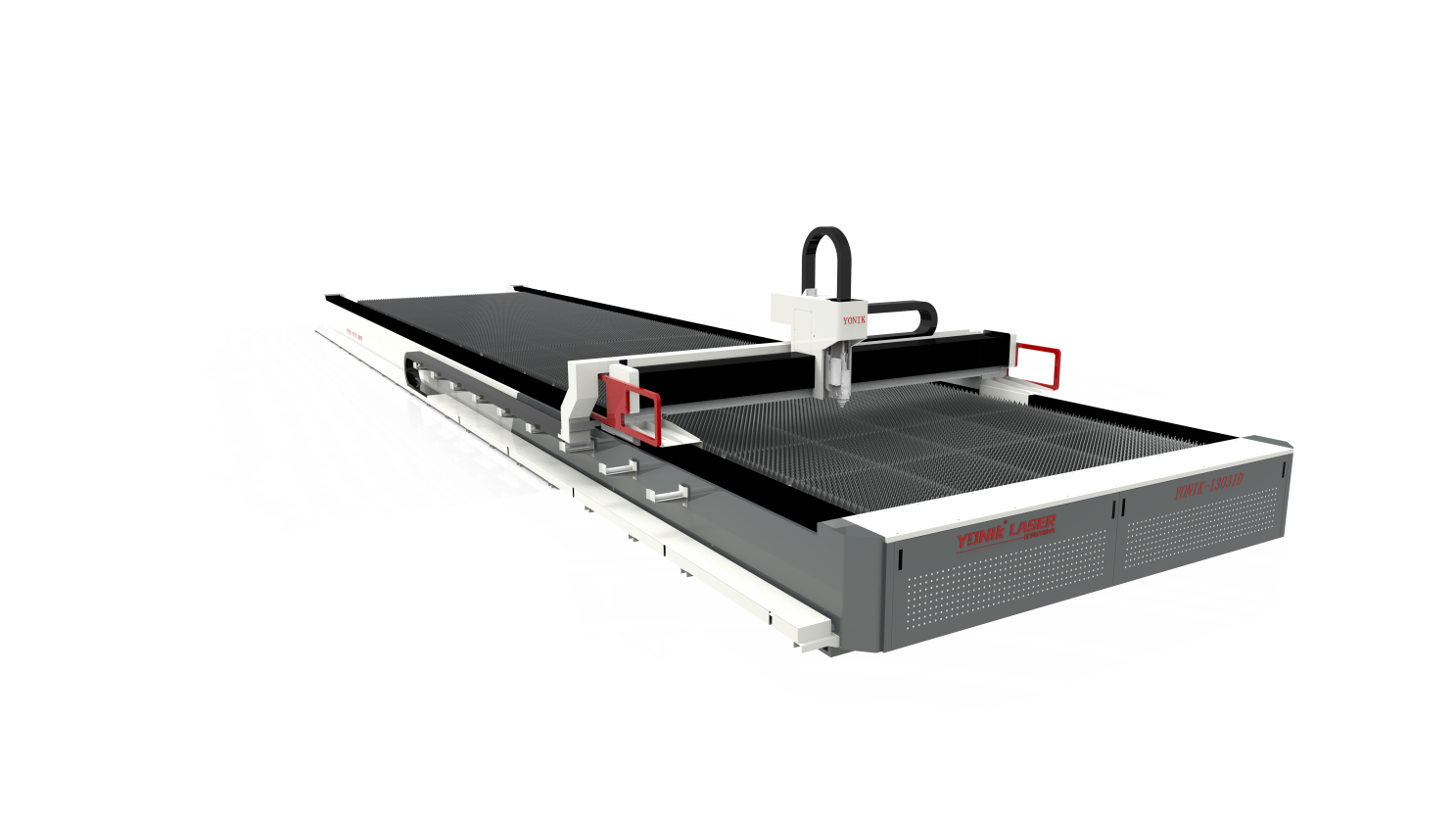

Single-Platform Laser Plate Cutting Machine

Single-Platform Laser Plate Cutting Machine (1) Machine Overview The fiber laser cutting machine is a cutting-edge piece of equipment designed for precision cutting of materials based on user requirements. A highly efficient alternative to traditional cutting methods such as flame cutting, CNC punching, and plasma cutting, our series of equipment boasts a bed made from top-notch plates. Crafted by skilled professionals through welding, secondary aging treatment, and precision

- Color: Default Color

- Size: Default Size

- Origin: China

- Usage: Default Usage

- Type: Default Type

- Efficiency: 99.9% Type

Description:

Single-Platform Laser Plate Cutting Machine

(1) Machine Overview

The fiber laser cutting machine is a cutting-edge piece of equipment designed for precision cutting of materials based on user requirements. A highly efficient alternative to traditional cutting methods such as flame cutting, CNC punching, and plasma cutting, our series of equipment boasts a bed made from top-notch plates. Crafted by skilled professionals through welding, secondary aging treatment, and precision machining using large gantry milling machines, this design ensures exceptional shock resistance, high rigidity, and stability.

The fixed supporting feet, connected to the frame, provide structural support, allowing for precise adjustment of the frames straightness. The machines bed, secured by fixed support feet, is fine-tuned for accuracy. Thick plate insulation covers the laser beam target area, preventing laser ablation and ensuring workpiece processing accuracy. The dust removal system, designed aerodynamically, guarantees a smooth flue path, effectively reducing dust removal fan capacity loss.

Featuring a simple structure, the workbench, with its gantry-type bed structure, significantly enhances load-bearing capacity. The single-platform machine tool with this bed structure exhibits twice the load-bearing capacity of ordinary machines, extending the machines service life. The slag discharge systems lower bed is equipped with a partition collection device, automatically gathering waste materials during production. The zoned dust collection design in the dust removal system workbench allows customization based on user needs.

The transmission system, equipped with imported gear racks, servo motors, reducers, and linear guides, ensures stability, high precision, and high-quality cutting capabilities. This setup highlights a more reasonable product structure, mature functionalities, and professionalism, guaranteeing high-precision, high-speed, and high-stability processing.

(2) Machine Performance

- Independent research and development of machine tool beds with special processing technology for high precision, stability, reliability, and long life.

- Precision rack and pinion drive with a high-precision reducer and responsive servo motor.

- Utilization of an internationally acclaimed fiber laser for long life, maintenance-free operation, and stability.

- High-precision laser cutting head with adaptive optics system, fine focus, easy adjustment, and impeccable cutting quality.

- User-friendly CNC system operation with low operator requirements.

- Versatile cutting graphics input in various formats and powerful drawing and editing functions.

- Automatic refueling system.

(3) Cutting Materials

Suitable for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel, galvanized sheet, pickled sheet, and other metal sheets. Widely used in manufacturing industries like engineering machinery, aerospace, automobiles, ships, steel structures, machinery manufacturing, elevators, advertising, household appliances, medical equipment, furniture, and metal external processing services.

2. Functional Characteristics of Each Part

(1) Fiber Laser Generator

The fiber laser generator, with its modular and redundant design, is compact, lightweight, and easy to integrate. It ensures stable performance, making it suitable for industrial applications such as welding, cutting, and cladding.

(2) Laser Cutting Head

- Completely sealed internal structure to prevent optical contamination.

- Driven by an imported motor for high perforation efficiency.

- Drawer-type installation for the protective lens, facilitating quick and easy maintenance.

- Adaptive optical system for automatic focus adjustment, ensuring consistent cutting quality.

- Minimum gas consumption guaranteed, with automatic machine stop in case of a cutting head collision.

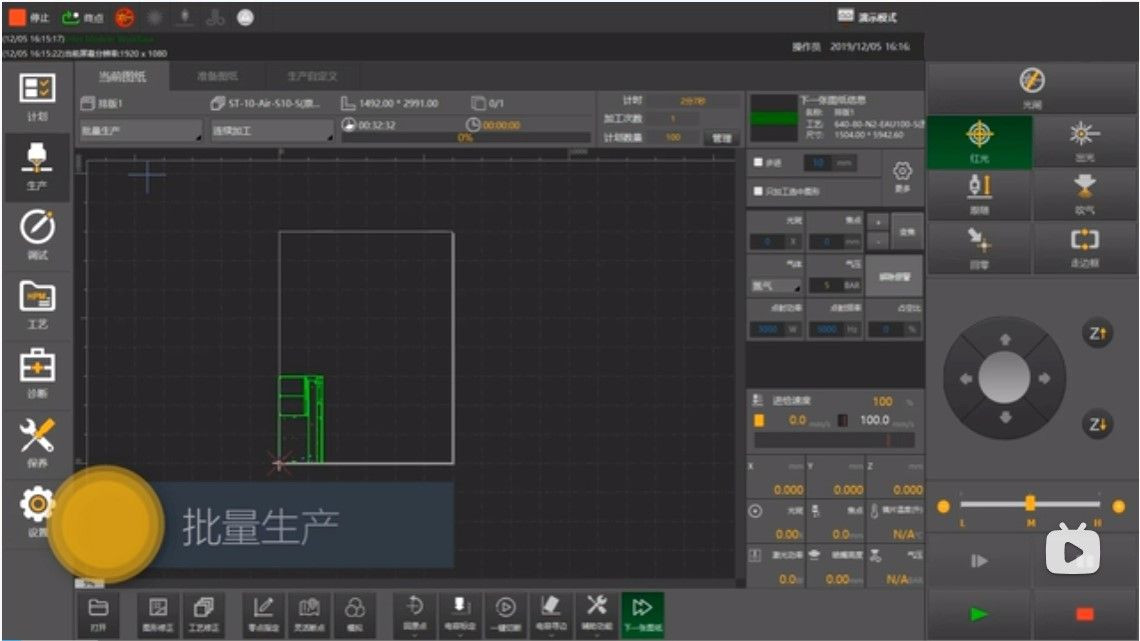

(3) Operating System

- Separation of processing and layout with support for necessary graphics optimization functions.

- Plan supports interconnection with CypNest for remote network push processing tasks.

- Process-guided and multi-threaded production planning operations for improved operator safety and reduced equipment downtime.

- Debugging block supports various graphic data formats for efficient proofing and debugging.

- Diagnostic Jiugongge mode integrates equipment management and data statistics.

- Maintenance module offers equipment status analysis and suggests repairs and maintenance based on preset warning thresholds.

- Visual assistance for residual material production and safety monitoring.

(4) Operating Software (Optional)

Specially developed drawing programming and nesting software for CNC cutting machines, featuring CAD drawing, DXF/DWG optimization, interactive nesting, automatic programming, and cutting simulation verification.

(5) Cooling Method

Professional-grade water cooling system with dual temperature and dual control. The refrigeration unit automatically cools when the water temperature exceeds the specified level and stops cooling when the temperature drops below the specified threshold.

Description:

The Single-Platform Laser Plate Cutting Machine from Jinan Hengchen Industrial Trade Co., Ltd. is a state-of-the-art fiber laser cutting solution engineered for precision, durability, and operational efficiency. This machine stands as a superior alternative to traditional cutting methods such as flame cutting, CNC punching, and plasma cutting, offering enhanced performance and reliability.

At the heart of its design is a robust bed constructed from high-quality plates, meticulously welded and subjected to secondary aging treatment. Precision machining using large gantry milling machines ensures exceptional shock resistance, rigidity, and stability. The fixed supporting feet, integrated into the frame, provide structural support and allow for precise adjustments, maintaining the straightness and accuracy of the machine.

633

633